Cyclone Separators

A cyclonic separation is a method of removing particulates from an air, gas or liquid stream, ... and marketing bagless vacuum cleaners based on cyclonic separation of dust, initially inspired by seeing a sawdust separator at a sawmill.

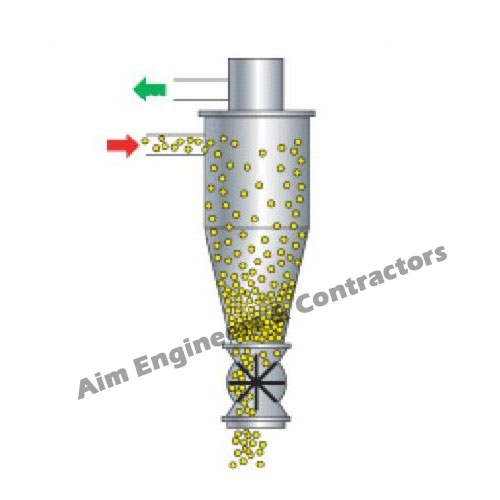

A high speed rotating (air) flow is established within a cylindrical or conical container called a cyclone. Air flows in a spiral pattern, beginning at the top (wide end) of the cyclone and ending at the bottom (narrow) end before exiting the Cyclone Separators in a straight stream through the center of the cyclone and out the top. Larger (denser) particles in the rotating stream have too much inertia to follow the tight curve of the stream and strike the outside wall, falling then to the bottom of the cyclone where they can be removed. In a conical system, as the rotating flow moves towards the narrow end of the Cyclone Separators the rotational radius of the stream is reduced, separating smaller and smaller particles.

Applications of Cyclone Separator:

General applications include:

oil refineries to separate oils and gases

cement industry

vacuum cleaners

Features Required :

High efficiency over a broad flow range

Flow-optimized design

Low pressure drop resulting in energy savings

High safety during operation under pressure

Long-term corrosion protection

Additional Information:

Pay Mode Terms: T/T (Bank Transfer)

Established in the year 1995 at Ghaziabad, (Uttar Pradesh, India), we “Aim Engineers & Contractors” are a Sole Proprietorship Firm, known as the reputed Manufacturer of High Pressure Tanks, Heat Exchangers, Material handling systems, Conveyors, Nylon Gears, Canteen Table, Steel Blower Wheel, etc.